Solution visuelle pour la gestion de la maintenance

Our Solution (MVM: Maintenance Visual Manager)

The gains of MVM :

- Lower maintenance costs.

- Reducing the failure rate.

- Optimization of resource availability.

- L’optimisation des temps d’arrêt des équipements.

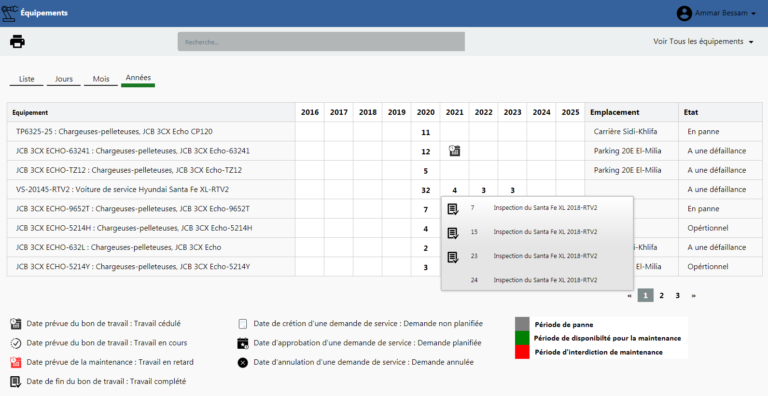

- A complete view of the status of equipment, locations and associated work.

Our product is maintenance management software that allows you to operate your equipment in the best conditions.

- La surveillance et l’analyse de l’état des équipements, des bâtiments et des emplacements.

- L’identification efficace des travaux de maintenance et de réparation.

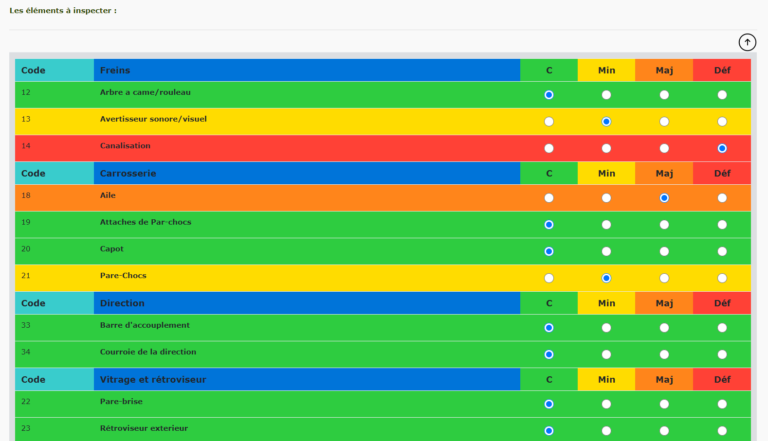

- La planification et l’ordonnancement des inspections et du travail préventif.

- Optimization of repairs to minimize the risk of hazards.

- Prioritization and scheduling of maintenance resources.

- La planification des temps d’arrêt pour la maintenance.

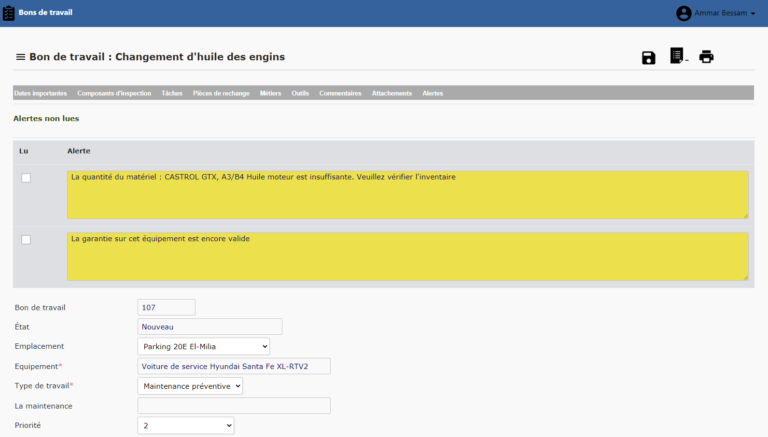

- Monitoring of the performance of maintenance work.

- Efficient inventory management to optimize the availability of spare parts.

- Quick and efficient access to historical data of equipment and maintenance work.

- The availability of reports based on best practices in maintenance management.

- A business solution accessible on the internet.

- Rich and easy to use user interfaces.

The system is composed of several modules

Différents modules du logiciel ont été pensé et réfléchi pour vous permettre d’avoir un contrôle complet du processus de maintenance de A à Z.

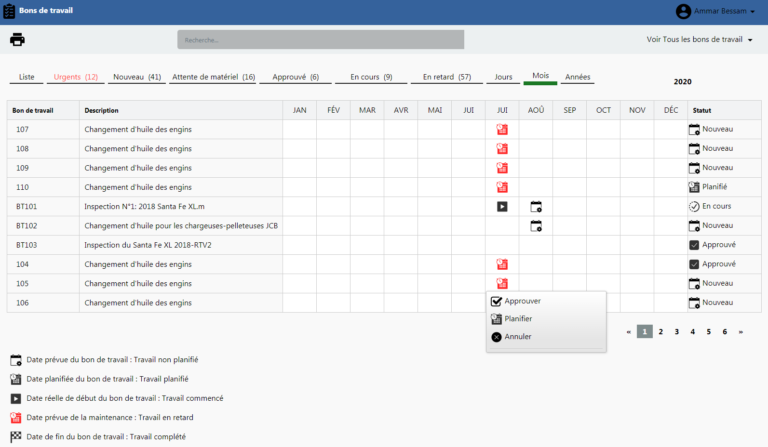

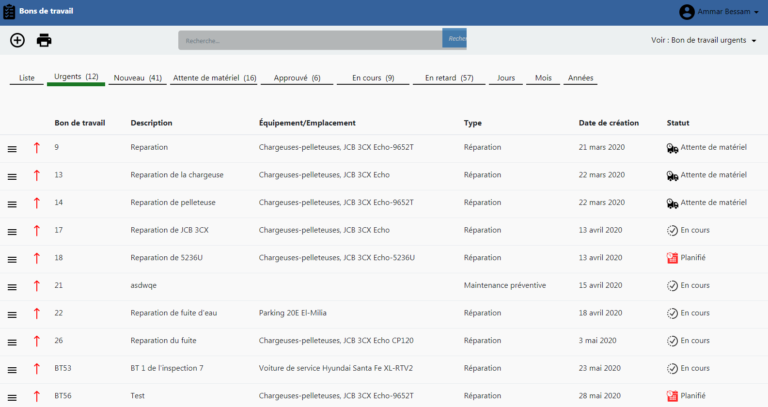

Proactive and corrective maintenance

Performing maintenance

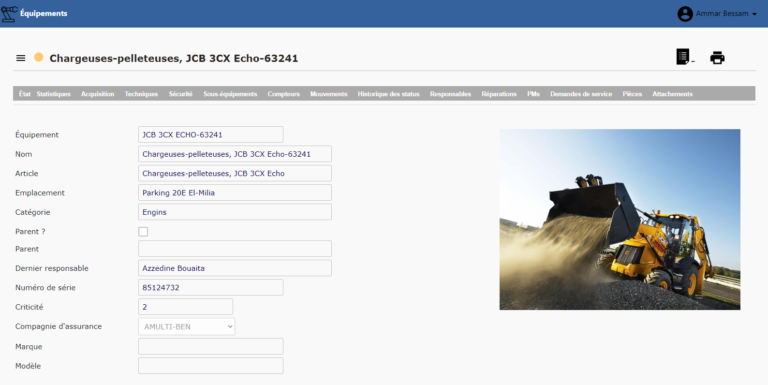

Managing your equipment

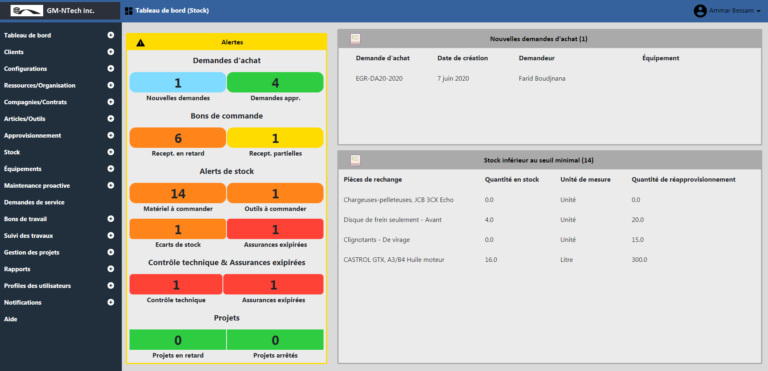

Inventory management

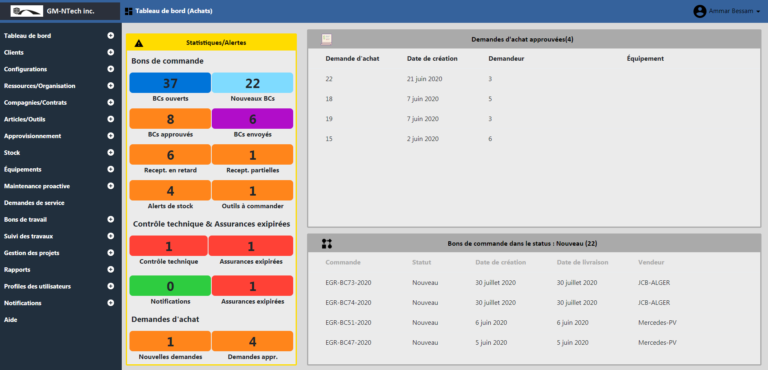

Supply Management

Maintenance staff

Reports and KPIs

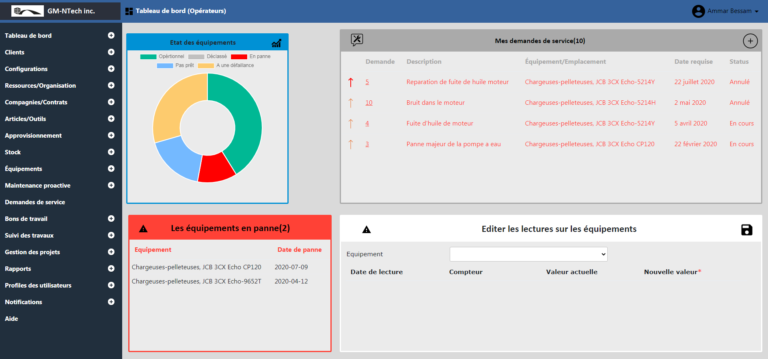

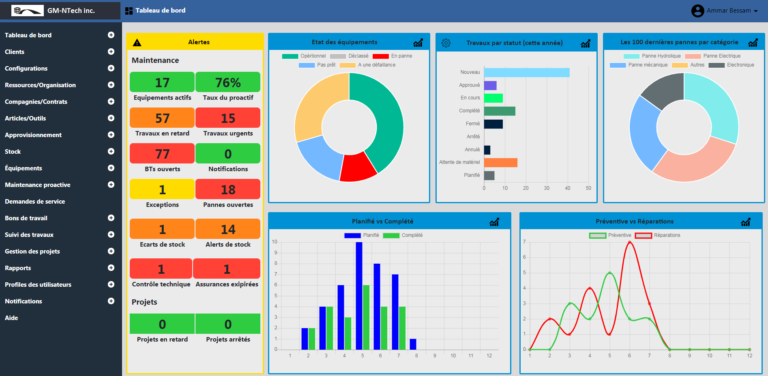

Dashboard

A single interface to monitor the metrics needed to conduct maintenance in your business and measure the important factors to know the condition of your equipment and the maturity of the maintenance process.

In both graphical and visual format, our product gives you a summary of all transactions, exceptions and important events in your maintenance department.

- Contracts to be renewed

- Urgent work

- The preventive rate in your maintenance management

- The rate of downtime of your equipment

- The late work rate

- A view of the status of maintenance work orders

- Stock alerts

Q&As

MVM (Maintenance Visual Manager) is a maintenance management system based on graphical interfaces and easy-to-use calendars for a simple but efficient management of maintenance work as well as for visualization of the frequencies of preventive and conditional maintenance programs and inspections.

Truck companies (give the right name), - Car garages (give the right name), - All SMEs that have maintenance and repair work on their equipment.

Tout dépend des modules à utiliser et de votre engagement, une implémentation complète pourrait être prête pour l’opérationnalisation dans une durée de 15 jours. Cela inclut la configuration des données de base de l’entreprise et la formation des super utilisateurs.

Les interfaces du système sont très conviviales et intuitives. Avec l’utilisation du guide de l’utilisateur du système, Un utilisateur principal du système pourrait être capable d’opérer MVM après 5 jours de formation.

To start with each customer, our system experts take care of providing direct to customer demonstrations on site or remotely.

Google chrome

- Monitoring and analysis of the condition of equipment, buildings and locations.

- L’identification efficace des travaux de maintenance et de réparation.

- La planification et l’ordonnancement des inspections et du travail préventif.

- L’optimisation des réparations pour minimiser les risques de dangers.

- La priorisation et l’ordonnancement des ressources de maintenance.

- La planification des temps d’arrêt pour la maintenance.

- Monitoring of the performance of maintenance work.

- La gestion efficace de l’inventaire pour optimiser la disponibilité des pièces de rechange.

- La gestion efficace et intuitive de tous le processus d’approvisionnement des articles de maintenance.

- L’accès rapide et efficace aux données historiques des équipements et des travaux de maintenance.

- The availability of reports based on best practices in maintenance management.

Oui, toutes les solutions sont opérationnelles sur le Web. MVM pourrait être déployé en local dans l’entreprise ou sur le CLOUD.